What are the things to be concerned about in the research and development of IVD upstream raw materials and reagents

Release time:

2025-09-13

In the in vitro diagnostics (IVD) industry, the research and development of upstream raw materials and reagents is the foundation of the entire industry chain, and their quality and performance directly determine the quality, stability, and clinical application value of downstream diagnostic reagents. With the rapid development of the IVD market, the requirements for raw materials and reagents are becoming increasingly stringent. From bioactive raw materials to chemical auxiliary materials, from optimizing production processes to improving quality control systems, many key issues require the attention of R&D personnel.

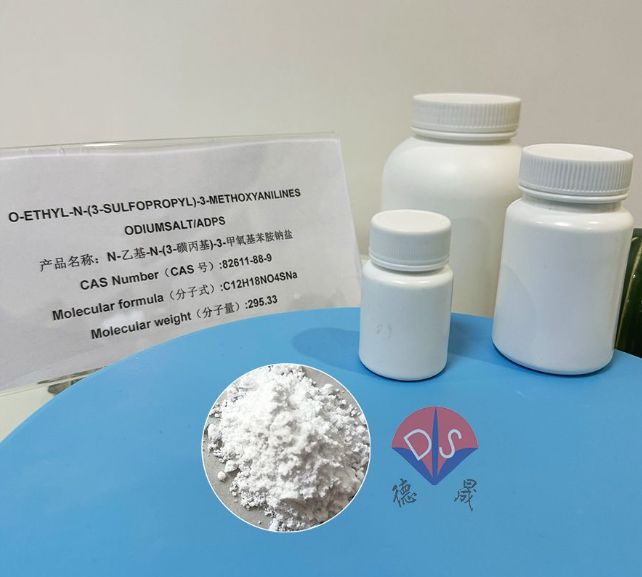

Chromogenic substrate ADPS

Selection of raw materials and performance evaluation

1. Key indicators of bioactive raw materials

In IVD reagents, bioactive raw materials such as antigens, antibodies, and enzymes are important. Taking antigens as an example, whether they are natural antigens or recombinant antigens, their specificity and stability are the core indicators. In the development of infectious disease diagnostic reagents, the molecular design of recombinant antigens needs to accurately simulate the key epitopes of pathogens to ensure binding with corresponding antibodies. When developing antibodies, polyclonal antibodies need to optimize immunogens, immunized animals, and immunization programs to enhance antibody potency and specificity; Monoclonal antibodies should focus on screening and culturing hybridoma cells to ensure their ability to recognize specific antigenic epitopes. Enzyme raw materials, such as various tool enzymes used for biochemical diagnosis, directly affect the detection results in terms of their activity, catalytic efficiency, and stability. For example, in blood glucose detection reagents, the activity of glucose oxidase determines its catalytic ability towards glucose, which in turn affects the determination of blood glucose concentration.

2. Quality control of chemical raw materials

Chemical raw materials are used in IVD reagents for the preparation of buffer solutions, stabilizers, etc. The purity, pH value, impurity content, and other indicators of commonly used trihydroxyaminomethane buffer solutions need to be strictly controlled. In nucleic acid amplification reagents, the pH stability of the buffer system is crucial for the PCR reaction, and even small pH deviations can affect the activity of Taq enzyme, thereby interfering with the nucleic acid amplification effect. In actual research and development, it is necessary to select chemical raw materials that meet the requirements of different methods for in vitro diagnostic products, and strictly inspect each batch of raw materials, including appearance, general salt testing, heavy metal testing, and other items.

Optimization and stability of production process

For chemical raw materials, if synthesis processes are involved, reaction conditions need to be optimized to ensure stable product quality. During the compounding process of buffer solutions, accurately control the proportions of each component to ensure that parameters such as buffering capacity and ionic strength meet design requirements. Taking the coating buffer of ELISA kit as an example, the proportion of each chemical substance in its formula directly affects the coating effect of antigen or antibody on the solid-phase carrier, thereby affecting the detection sensitivity and specificity. During the research and development process, it is necessary to conduct extensive experimental verification and process optimization to determine ideal compound process parameters, and establish standardized operating procedures to ensure the stability of the production process.

Establishment and improvement of quality control system

Establishing comprehensive and strict raw material quality testing standards is an important aspect of research and development. For bioactive raw materials, indicators such as appearance, purity, potency, specificity, sensitivity, stability, and inter batch differences need to be tested. The quality standards for chemical raw materials cover aspects such as appearance, solution pH, heavy metal detection, solubility, and drying loss. Different raw materials are tested and qualified according to their characteristics and application scenarios to ensure reliable quality of the materials put into use.

Meanwhile, quality monitoring throughout the entire process, from raw material procurement, production preparation to finished product packaging, is indispensable. In the raw material procurement process, suppliers are required to provide detailed quality assurance materials and inspection reports, and conduct random inspections on each batch of raw materials. During the production process, key quality control points are set up to monitor process parameters and product quality indicators in real-time. Before packaging the finished product, quality inspection is carried out, and only products that meet quality standards can enter the market circulation process.

Responding to market demand and industry development trends

With the diversified development of the IVD market, different application scenarios have put forward diverse demands for raw materials and reagents. R&D personnel need to keep up with market trends and develop raw materials and reagents that are suitable for different detection platforms and application scenarios. For the research and development of POCT blood glucose meters for grassroots institutions, emphasis should be placed on cost control and operational convenience; The raw materials used for molecular diagnostics such as gene sequencing need to continuously improve their performance to meet the demand for accurate detection of trace nucleic acids.

Currently, the IVD industry is facing the bottleneck problem of relying on imported core raw materials, while supply chain stability is also highly valued. R&D personnel should actively engage in the localization of raw materials and break through import monopolies through technological innovation. On the one hand, domestic enterprises need to increase their R&D investment, enhance their independent R&D capabilities, and develop raw materials and reagents with performance comparable to or even better than imported products; On the other hand, strengthening cooperation between upstream and downstream of the industrial chain, midstream reagent manufacturers provide application needs and feedback to upstream raw material enterprises, and jointly optimize product performance. During the research and development process, emphasis is placed on establishing a stable and reliable supply chain system, reducing reliance on a single supplier, ensuring the continuity and stability of raw material supply, in order to address potential supply chain risks.

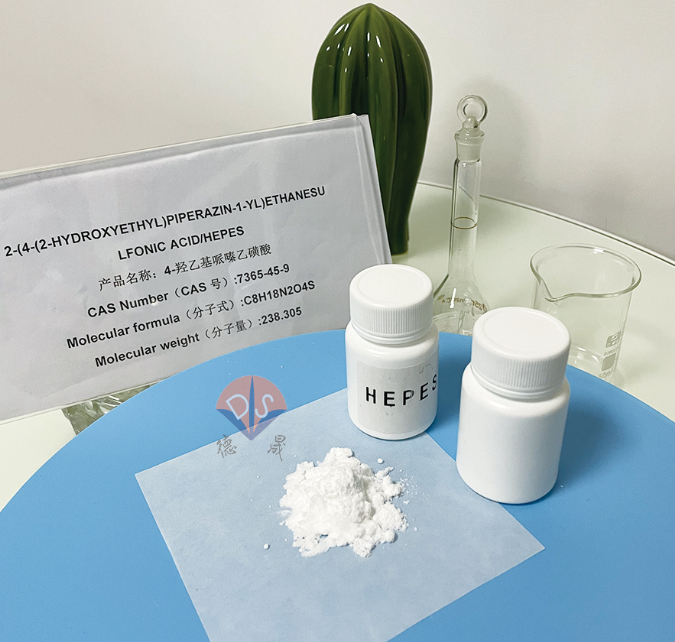

Biological buffer HEPES

The research and development of IVD upstream raw materials and reagents is a complex and systematic project, from raw material selection, process optimization, quality control to market adaptation, each link is related to product quality and industry development. R&D personnel need to comprehensively consider multiple factors, continuously innovate and optimize, and provide high-quality and high-performance raw materials and reagents for the IVD industry. As an upstream raw material and reagent supplier for IVD, Hubei Xindesheng Company focuses on core products such as biological buffering agents, luminescent reagents, and colorimetric reagents, providing stable raw materials for downstream customers. Its products cover multiple fields such as biochemical diagnosis and immunological diagnosis, ensuring purity and activity standards through optimized processes, and adapting to different testing scenarios. The company has established a comprehensive quality control system to monitor the entire process from raw materials to finished products, ensuring batch stability and becoming a reliable partner in the upstream of the IVD industry chain. If you have any purchasing needs, please feel free to contact us at any time!

Previous page

Previous page

News

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us