2-morpholine ethanesulfonic acid (MES): a promoter in electroplating additives

Release time:

2025-09-06

In today's electronic manufacturing field, with the development of integrated circuit technology towards smaller size features, the quality requirements for interconnect structures are increasingly increasing. Among them, the electroplating copper process is one of the key steps in constructing these high-density interconnect structures, and its quality directly affects the performance and reliability of the final product. Behind this, various electroplating additives play an indispensable role, especially the promoter represented by 2-methylmorpholine ethanesulfonic acid (MES buffer).

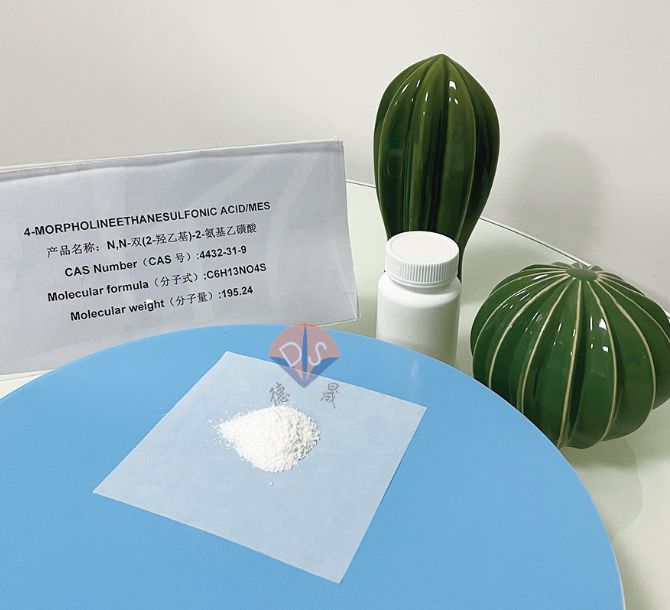

MES powder

Chemical properties of MES

MES, as a white solid powder, exists stably at room temperature and pressure, and its molecular structure contains a morpholine ring and an ethanesulfonic acid group. The morpholine ring endows MES with high stability and inertness, enabling it to maintain good chemical stability in complex electroplating environments. Meanwhile, the presence of ethanesulfonic acid groups endows MES with excellent water solubility and buffering capacity, which is crucial for maintaining the pH value of the plating solution and providing a uniform metal deposition environment. It is precisely because of these characteristics that MES exhibits excellent promoting effects in electroplating additives.

Application in electroplating process

The role of MES as a promoter in the electroplating process cannot be ignored. It forms complexes with metal ions to reduce the activation energy on the electrode surface, thereby accelerating the rate of electrochemical reactions and promoting the reduction deposition of metal ions on the cathode. This mechanism of action not only helps to improve electroplating efficiency, but also effectively reduces defects that may occur during pore and groove filling, ensuring defect free filling and flatness of the interconnect structure. Especially when dealing with holes with smaller feature sizes, the promoting effect of MES is particularly significant, improving the consistency and smoothness of the plating layer, providing favorable conditions for subsequent chemical mechanical polishing and other processes.

Synergistic effects with other components

MES does not work alone, but works together with other additives such as inhibitors, leveling agents, etc. The synergistic effect between these components can further optimize the electroplating process, ensuring uniform distribution of coating thickness even in areas with significant differences in wiring density, reducing the technical difficulty of subsequent processes. For example, when MES is combined with thiourea accelerators, they can complement each other, improve the overall electroplating effect, and achieve more ideal electroplating results.

Product packaging

Hubei Xindesheng: A professional supplier of MES

Among numerous MES production enterprises, Hubei Xindesheng stands out with its professional products and services. As a company dedicated to the research and development, production, and sales of MES and other biological buffer products, Xindesheng is committed to providing customers with high-quality MES products. The company relies on advanced production technology and strict quality control system to ensure that every batch of MES meets the requirements of the enterprise and satisfies customers' demanding requirements for product quality. Choosing Xindesheng means choosing reliability and trust. Let's work together to create a better future!

Previous page

Previous page

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us