Is it feasible for IVD upstream raw materials to adopt a low price strategy in the current market environment

Release time:

2025-09-03

In the vast ecosystem of in vitro diagnostics (IVD) industry, upstream raw materials serve as the foundation of the entire industry, and the choice of market strategy is crucial. The low price strategy has been frequently adopted in the upstream raw material market of IVD in recent years. However, whether this strategy is feasible in the current complex and ever-changing market environment needs to be analyzed from multiple aspects.

1、 Preliminary Examination of Market Competition Pattern and Low Price Strategy

The upstream raw material market for IVD is fiercely competitive, with a large number of enterprises. According to relevant statistics, there are over 300 raw material enterprises in China, and such a large number of enterprises leads to a highly dispersed market. In this pattern, some companies attempt to gain competitive advantage through low price strategies, hoping to expand market share and stand out in the competition.

Taking the biochemical diagnostic raw material market as an example, many domestic enterprises are concentrated in the mid to low end field, and product homogenization is severe. In order to compete for a limited market, some companies engage in price wars, repeatedly lowering product prices. This kind of low price competition may attract some price sensitive customers in the short term, allowing companies to obtain order volume. However, in the long run, the drawbacks of this strategy are gradually becoming apparent. Long term low-priced sales have compressed the profit margin of enterprises, and the meager profits are difficult to support sustained R&D investment, limiting the improvement of product quality and the launch of new products, which may lead to the loss of competitiveness of enterprises in the market.

2、 Consideration of product quality and customer needs

The quality of IVD products is directly related to the accuracy of diagnosis, therefore, downstream customers have high requirements for the quality of raw materials. Although a low price strategy may attract some price sensitive customers, for most customers who value product quality, excessively low prices often raise doubts about product quality. Even if some low-priced raw materials perform "usable" in preliminary testing, there may be significant differences in key indicators such as long-term stability and batch consistency compared to high-quality raw materials. This quality uncertainty makes customers more cautious when choosing raw materials, and they will not easily switch suppliers just because of low prices. So, relying solely on a low price strategy is difficult to meet the market's core demand for high-quality raw materials, nor can it establish a long-term stable customer base in the market.

3、 The contradiction between cost structure and development

The production of IVD upstream raw materials involves multiple stages such as research and development, production, and quality control, each of which requires significant investment in costs. In terms of research and development, developing new raw material products and optimizing the performance of existing products require a significant investment of manpower, material resources, and financial resources to meet the constantly changing market demands and technological development trends. During the production process, costs such as raw material procurement, equipment maintenance, and personnel salaries should not be underestimated.

When companies adopt a low price strategy, they often have to cut costs in order to maintain profits. Possible choices include lowering raw material procurement standards, reducing research and development investment, or lowering the strictness of quality control. Although these practices can lower product prices in the short term, in the long run, they will seriously affect product quality and the development ability of the enterprise.

4、 The impact of domestic substitution and supply chain

In the current complex and ever-changing trade situation, the domestic substitution of IVD upstream raw materials has become a focus of industry attention. For a long time, China's IVD raw material market has been highly dependent on imports, with key raw material imports accounting for over 80%. This excessive dependence on imported raw materials poses a risk of supply chain instability for the domestic IVD industry. In the process of promoting domestic substitution, price factor is indeed an important competitive advantage. If domestic raw material enterprises can provide competitively priced products while ensuring product quality, it will help accelerate the process of domestic substitution and improve the supply chain security of the domestic IVD industry. However, the low price strategy cannot come at the cost of sacrificing product quality and technological innovation. Enterprises need to find a balance between price, quality, and technological innovation, gradually breaking the monopoly of imported brands and achieving the development of domestic raw materials by improving their own technological level and product quality. If relying solely on low price competition, although it may gain market share in the short term, it is difficult to fundamentally enhance the competitiveness of domestic raw materials and cannot truly guarantee the stability of the supply chain.

Although in certain specific situations, a low price strategy may lead to market share growth in the short term, in the long run, there are many contradictions with the market's high requirements for product quality, the cost structure and development goals of enterprises. IVD upstream raw material enterprises should pay more attention to product quality improvement, technological innovation, and customer service, and obtain market advantages through differentiated competition to achieve long-term stable development of the enterprise, rather than relying solely on low price strategies.

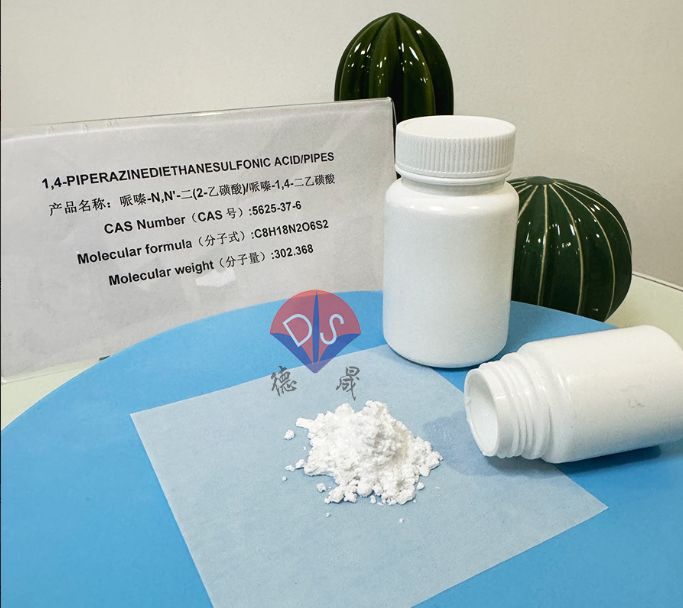

As an IVD raw material supplier, Hubei Xindesheng adheres to technological innovation and quality improvement as its core competitiveness. The company is deeply involved in the fields of biological buffering agents, chemiluminescence reagents, etc. By optimizing the synthesis process and strictly controlling the quality control system, the purity and batch stability of the products are ensured. For example, the purity of HEPES buffering agents is over 99%, and the luminescence of acridine ester luminescent reagents is sensitive. At the same time, Xindesheng focuses on the needs of segmented fields and provides customized raw material services for customers. If you have any purchasing needs, please feel free to contact us at any time!

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us