Quality control: methods to ensure the quality of the prepared luminol solution

Release time:

2025-08-13

Luminol, as a key reagent widely used in various fields such as chemiluminescence analysis, forensic science, and biological detection, the quality of its solution directly affects the reliability of experimental results. In order to ensure the quality of the prepared luminol solution, strict control is required from multiple key links.

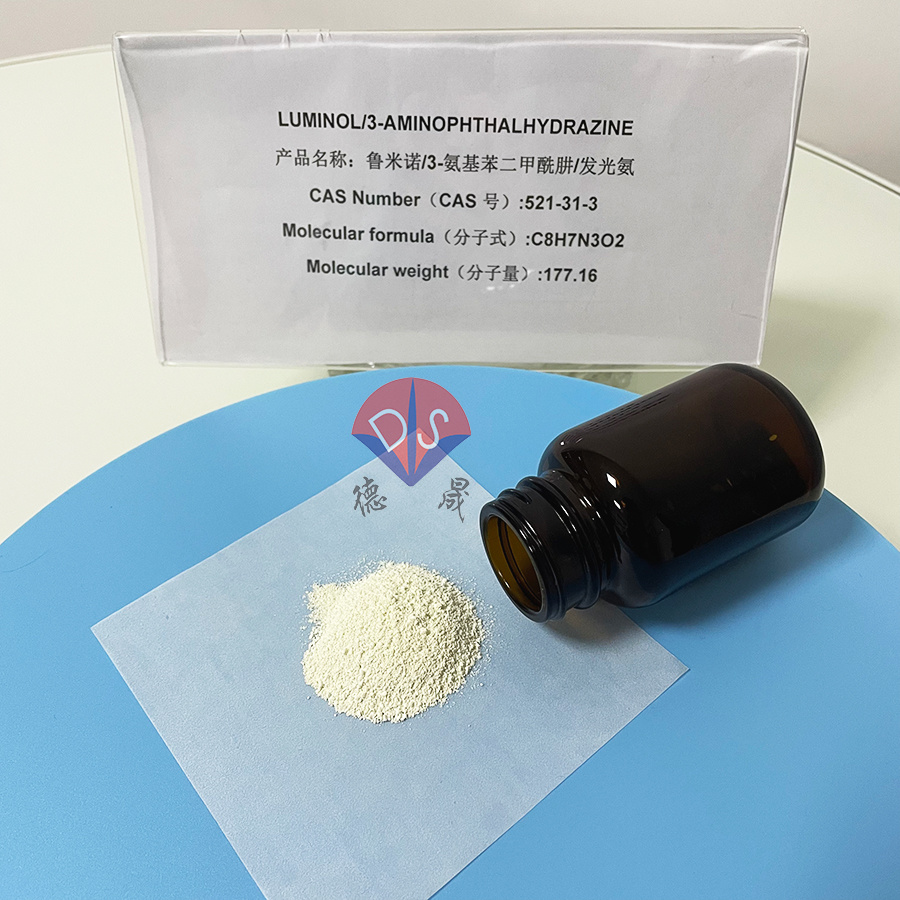

Luminol powder

Raw material selection and inspection

1. Purity control of Luminol raw materials: In the procurement process, choose suppliers with good reputation and guaranteed quality, and prioritize selecting products that meet industry standards or certifications. High purity luminol should typically achieve a purity of 98% or higher, with extremely low impurity content, which can reduce the instability of solution luminescence performance and increase background noise caused by impurity interference. When receiving raw materials, the laboratory should have inspection capabilities and can use precision analysis techniques such as liquid chromatography (HPLC) and mass spectrometry (MS) to randomly check their purity, ensuring that the purity of the raw materials meets expectations.

2. Solvent quality monitoring: Common solvents for luminol solution include sodium hydroxide solution, water, etc. For sodium hydroxide solution, attention should be paid to its concentration accuracy, as this will affect the dissolution of luminol and the pH environment of subsequent chemiluminescence reactions.

Accurate operation during the preparation process

1. Weighing accuracy guarantee: Accurate weighing is an important step in preparing luminol solution, which requires the use of high-precision electronic balances. Before weighing luminol powder, it is necessary to ensure that the balance is calibrated and in a stable working environment. Accurately calculate and weigh the mass of luminol according to the required concentration and volume for the experiment. During the operation, prevent the powder from spilling. For small amounts of spilled powder, do not recycle it into the weighing container at will to avoid introducing errors.

2. Specification for dissolution and mixing steps: Slowly add the weighed luminol powder into the pre prepared solvent, stirring while adding to ensure even dispersion of the luminol powder and prevent clumping. If sodium hydroxide solution is used to dissolve luminol, the alkaline solution should be slowly added dropwise and stirred continuously, while monitoring the pH value of the solution to maintain it within a suitable range for luminol dissolution and stable luminescence.

Solution storage and stability maintenance

1. Storage container selection: A suitable storage container is important for maintaining the quality of luminol solution. Brown glass bottles can be used, which can block ultraviolet radiation because luminol solution is sensitive to light and can decompose under prolonged light exposure, reducing its luminescence performance. The material of glass bottles should have good chemical stability to avoid chemical reactions with luminol solution. The inner wall should be smooth to reduce residual adsorption of the solution.

2. Optimization of storage conditions: Luminol solution should be stored in a low-temperature, dark, and dry environment. Low temperature environment can significantly slow down the chemical reaction rate and reduce the decomposition rate of luminol. The laboratory refrigerator needs to be regularly cleaned and maintained to ensure a constant temperature and avoid frequent temperature fluctuations caused by opening and closing the refrigerator door. Regularly conduct quality checks on stored luminol solutions, by detecting their chemiluminescence intensity, pH value, and other indicators, potential problems can be identified in a timely manner. If a decrease in solution quality is found, the use should be stopped and the cause analyzed.

Quality inspection and verification

1. Chemiluminescence performance testing: Chemiluminescence performance is the core indicator of the quality of luminol solution, and it needs to be regularly tested using a chemiluminescence analyzer. If the luminescence intensity is too low or decays too quickly, it indicates that there may be a problem with the quality of the solution.

2. Impurity content analysis: Analyze the impurity content in the luminol solution, focusing on impurities that may affect the luminescence performance, such as heavy metal ions, unreacted raw materials, and synthetic by-products. Set reasonable impurity content standards.

Product packaging

As a manufacturer of luminescent reagent raw materials, Hubei Xindesheng can provide analytical grade, fast luminescence, bottle light avoidance, and stable performance. At present, we have established cooperative relationships with multiple enterprises and can provide long-term stable supply. If you have purchasing intentions, please feel free to click on the website for consultation at any time!

Previous page

Previous page

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us