Three key elements of IVD reagent raw material quality control

Release time:

2025-06-11

In the in vitro diagnostics (IVD) industry, the quality of reagent raw materials is the core factor determining the accuracy and reliability of diagnostic reagents, directly related to the quality of clinical diagnosis and patient health. Strict quality control is essential to achieve the quality of IVD reagent raw materials. The control of raw material sources, production process management, and quality inspection and evaluation constitute the three key elements of IVD reagent raw material quality control. They are interrelated and progressive, jointly safeguarding the quality of raw materials.

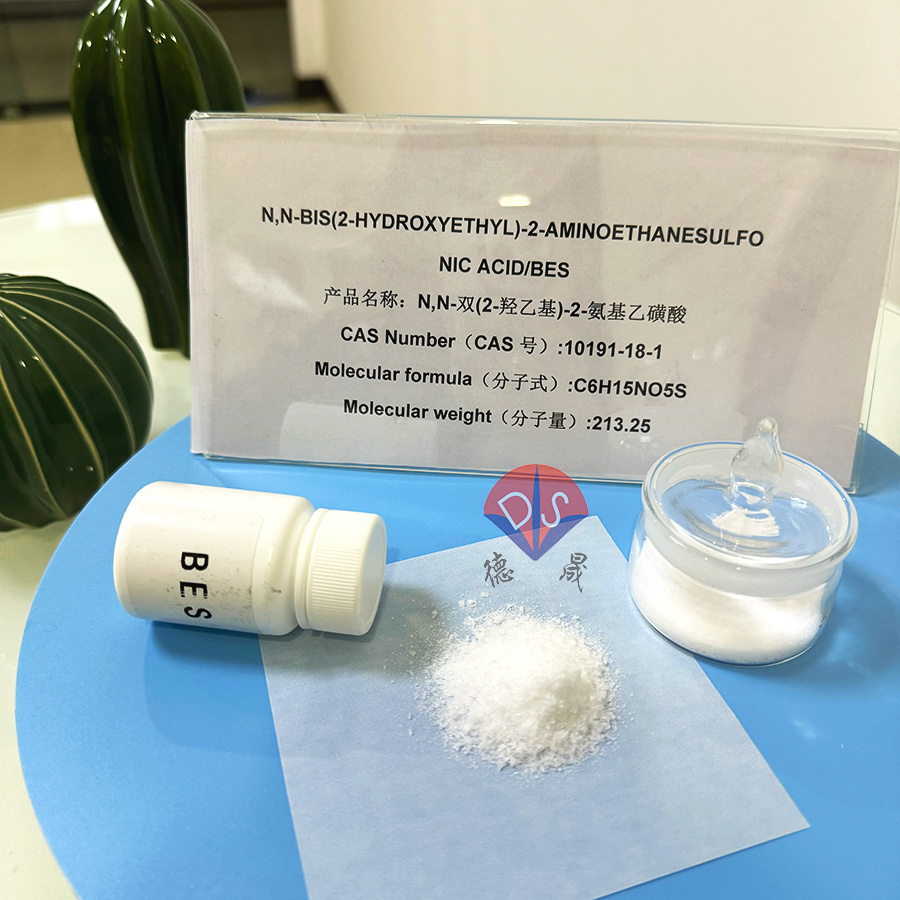

(Biological buffer BES)

Source control of raw materials: the foundation of quality control

1. Supplier screening and evaluation: IVD reagent raw material production enterprises need to establish a comprehensive supplier screening mechanism and conduct multi-faceted inspections of potential suppliers. Not only do we need to review the hardware conditions such as production qualifications, production equipment, and technical capabilities of suppliers, but we also need to evaluate their soft power such as quality management system and reputation. When selecting suppliers of biological raw materials, attention should be paid to whether their technology and purification processes are mature and whether the purity of the raw materials can be guaranteed. Through multidimensional evaluation, select suppliers with excellent qualifications and good reputation to establish cooperative relationships, and reduce raw material quality risks from the source.

2. Raw material acceptance and storage management: Raw material acceptance is an important link in controlling the source of raw materials. Enterprises should establish strict standards and procedures for raw material acceptance, and conduct sampling and testing on each batch of raw materials. The testing content covers key indicators such as appearance, purity, acidity and alkalinity of raw materials. Only raw materials that meet the standards can be stored.

Production Process Management: Ensuring Stable Quality

1. Standardized production process: Standardized production process is the key to ensuring stable quality of IVD reagent raw materials. Enterprises need to develop detailed and standardized production operating procedures, which provide clear regulations for every step of the production process, from raw material ratio and reaction condition control to product separation and purification. In the production of chemiluminescence reagent raw materials, accurate control of reaction temperature, time, reagent addition sequence and quantity parameters is necessary to ensure consistency in the synthesis process of each batch of products. By standardizing production, reducing the impact of human and environmental factors on product quality, and achieving stable output of product quality.

2. Personnel training and operational standards: The professional competence and level of operational standards of production personnel directly affect product quality. Enterprises should regularly organize professional training for production personnel, including knowledge of production processes, equipment operation skills, quality awareness, and other aspects. Familiarize production personnel with the operational requirements and quality standards of each production process, and master the methods to deal with unexpected problems in the production process. Establish a strict operational assessment system to ensure that production personnel can strictly follow the operating procedures and avoid quality problems caused by improper operation.

Quality Inspection and Evaluation: The Key to Qualified Quality

1. Multi angle detection indicators and methods: To ensure the quality of IVD reagent raw materials, it is necessary to establish a detection indicator system and scientific detection methods. Based on the characteristics and application requirements of the raw materials, determine the testing items, such as purity testing, stability testing, specificity testing, etc. Using advanced detection equipment and technology, such as liquid chromatography, mass spectrometry, enzyme-linked immunosorbent assay, etc., to accurately detect raw materials.

2. Strict quality traceability and feedback: Establish a comprehensive quality traceability system to record the entire process of each batch of raw materials from production to sales, including information on raw material sources, production process parameters, testing results, sales destinations, etc. Once there is a quality issue with the product, it can be quickly traced back to the root of the problem and timely measures can be taken to address it. At the same time, timely feedback of quality inspection results to the production and R&D departments provides a basis for improving production processes and product development, continuously improving product quality.

(Chromogenic substrate MAOS)

In terms of quality control of IVD reagent raw materials, Hubei Xindesheng Performance Company has always placed quality control in an important position since its establishment, strictly following the three elements of raw material source control, production process management, and quality testing and evaluation. In the process of raw material procurement, we have established long-term stable cooperative relationships with numerous suppliers, strictly inspected each batch of raw materials, adopted standardized production processes, strengthened personnel training and operational norms management, and established a sound testing system and quality traceability mechanism. With the persistent pursuit of quality control, Xindesheng's IVD reagent raw materials such as biological buffering agents and chemiluminescence reagents have won the trust of many customers in the market. If you have any purchasing needs, please feel free to contact us for consultation at any time!

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us