Optimization of Tris hydrochloride preparation conditions and their impact on product quality

Release time:

2025-06-09

Tris HCl, also known as Tris (hydroxymethyl) aminomethane hydrochloride, is an important biological buffering agent widely used in fields such as biochemistry and molecular biology. From protein purification to nucleic acid extraction, from cell culture to enzymatic reactions, Tris hydrochloride provides a suitable pH environment for experiments with its stable buffering properties, ensuring the accuracy of experimental results. However, the preparation conditions have a significant impact on the quality of the product, and optimizing the preparation conditions has become the key to improving the quality of Tris hydrochloride and meeting different application requirements.

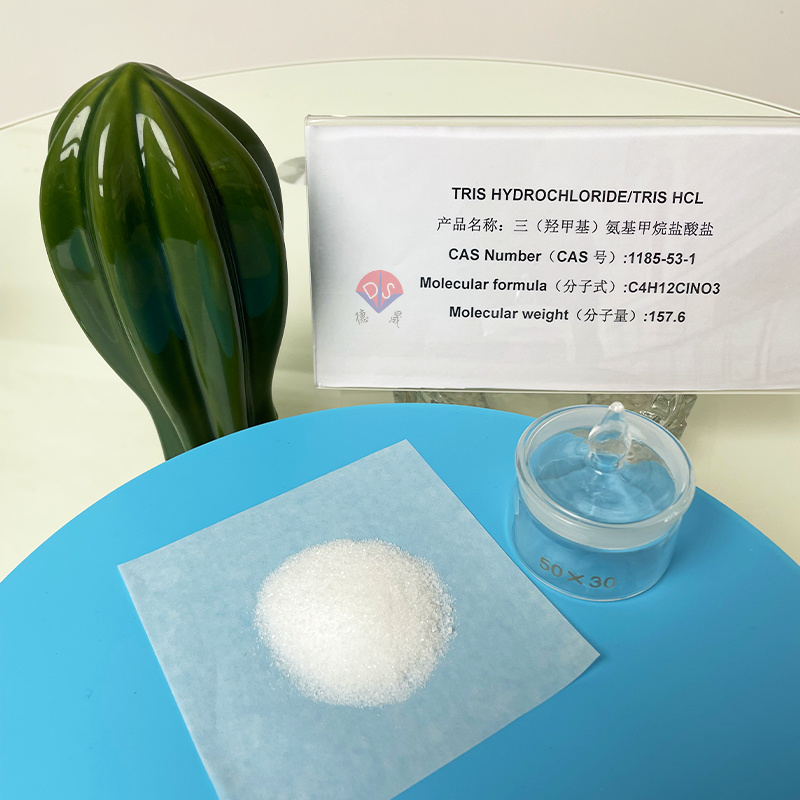

Tris HCl powder

The Influence and Optimization of Reaction Raw Materials on Product Quality

1. The key role of raw material purity: Tris hydrochloride is usually prepared using tris (hydroxymethyl) aminomethane (Tris) and hydrochloric acid as raw materials. The purity of raw materials directly affects the quality of products. If Tris raw materials contain impurities such as other amine substances or organic impurities, by-products may be generated during the reaction with hydrochloric acid, leading to a decrease in product purity. In nucleic acid extraction experiments, Tris hydrochloride with low purity may interfere with the reaction between nucleic acid and reagents, affecting extraction efficiency and quality. To ensure product quality, high-purity Tris and hydrochloric acid raw materials should be selected, and strict quality testing should be conducted on the raw materials to ensure that their various indicators meet the preparation requirements.

2. Optimization of raw material ratio: In theory, Tris reacts with hydrochloric acid in a specific molar ratio to produce Tris hydrochloride, but in practical operation, the amount of hydrochloric acid is usually adjusted appropriately to ensure the reaction proceeds fully. If the amount of hydrochloric acid is insufficient, Tris cannot react fully, resulting in residual unreacted Tris in the product, which affects the purity and buffering performance of the product; If too much hydrochloric acid is used, it may introduce excess chloride ions, change the ionic strength of the solution, and interfere with certain experiments.

The Influence and Control of Reaction Temperature on Product Quality

1. The effect of temperature on reaction rate and product: The reaction temperature has a significant impact on the preparation reaction rate and product quality of Tris hydrochloride. Raising the temperature can accelerate the reaction rate, allowing the reaction to reach equilibrium in a shorter period of time. However, excessive temperature may lead to side reactions, such as dehydration of hydroxyl groups in Tris molecules, generating other by-products and reducing product purity. Excessive temperature may also cause the volatilization of hydrochloric acid, resulting in inaccurate dosage of hydrochloric acid and affecting the composition and properties of the product.

2. Determination of suitable reaction temperature: To optimize the preparation conditions, it is necessary to determine the appropriate reaction temperature. Through a series of comparative experiments, Tris hydrochloride was prepared at different temperatures, and the purity, yield, and buffering performance of the product were analyzed. The experimental results indicate that the reaction can proceed smoothly at room temperature (20-25 ℃), with fewer side reactions and better product quality. In some large-scale production processes, the temperature can be fine tuned according to the actual situation, but it should be controlled within a specific range to avoid excessive temperature fluctuations affecting product quality.

The relationship between pH control and product quality

In the initial stage of the reaction, with the addition of hydrochloric acid, the pH value of the system gradually decreases. When the pH value reaches a specific range, Tris reacts fully with hydrochloric acid to form Tris hydrochloride salt. If the pH value is not properly controlled, it may lead to incomplete reaction or the generation of other by-products. The pH value is too high, resulting in a high amount of unreacted Tris; A low pH value may cause hydrolysis reaction of Tris hydrochloride and affect the stability of the product. During the reaction process, it is necessary to monitor the pH value in real time and adjust the amount of hydrochloric acid added in a timely manner according to the reaction progress to maintain the appropriate pH value. In actual production, precision pH meters can be used for monitoring, and the drip rate of hydrochloric acid can be accurately controlled through an automated control system to ensure that the pH value of the reaction system remains stable within an appropriate range.

Product packaging

In the field of biological buffering agents, Hubei Xindesheng Company, with years of research and production experience, has conducted in-depth research on the preparation conditions of Tris hydrochloride and continuously optimized the production process. In terms of raw material selection, we strictly control the quality and use high-purity raw materials to ensure product quality from the source; During the reaction process, accurate control of temperature, pH value, reaction time, and other conditions is carried out to ensure that each batch of Tris hydrochloride products has high purity, stable buffering performance, and good consistency. Its Tris hydrochloride product has gained widespread recognition in the market. If you have any purchasing needs, please feel free to click on the website for consultation at any time!

Previous page

Previous page

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us