No matter how good the dye is, unstable pH is useless: the key role of buffering agents in textile printing and dyeing

Release time:

2025-12-29

When it comes to biological buffers, most people first think of Tris HCl in PCR experiments, MOPS in electrophoresis systems, or HEPES in in in vitro diagnostic kits to maintain enzyme activity. However, the application of buffering agents goes far beyond these scenarios. In modern industrial production, especially in the textile printing and dyeing industry, buffering agents are playing a crucial role in a "moistening and silent" way.

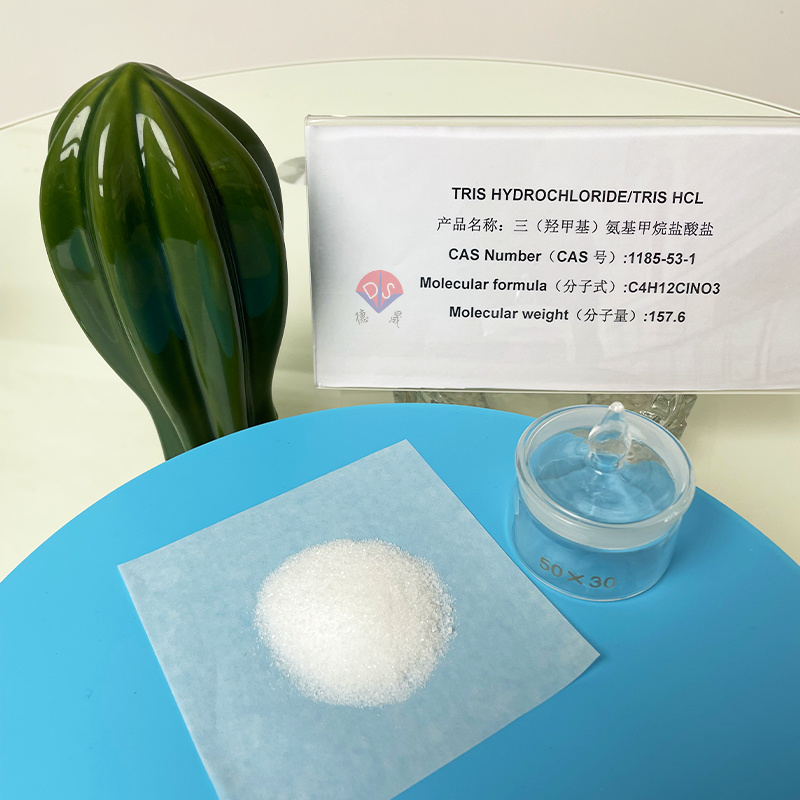

Tris HCl powder

The essence of buffering agents: maintaining pH stability

The core function of buffer solution is to maintain the relative stability of the pH value of the solution under external acid-base interference. It absorbs or releases hydrogen ions through a buffer pair composed of weak acid and its conjugate base (or weak base and its conjugate acid), thereby resisting pH fluctuations. This characteristic makes it a key additive for any process sensitive to acidic or alkaline environments. In biological systems, pH changes may affect enzyme activity, protein conformation, and even cell survival; In the industrial dyeing process, even small deviations in pH can lead to irreversible quality issues.

PH challenge in dyeing process: color difference and fixation issues

In textile printing and dyeing, the binding of dyes and fibers is highly dependent on the pH environment of the dyeing bath. Different types of dyes have different pH requirements:

Disperse dyes are used for polyester dyeing, usually under weakly acidic (pH 4.5-6.0) conditions. If the pH is too high, the dye will hydrolyze, resulting in a lighter color;

The weakly acidic dye used for wool dyeing needs to be within the pH range of 4.0-5.5 to achieve uniform dyeing, and pH loss of control can easily cause discoloration and spots;

Reactive dyes are mostly fixed under alkaline conditions (pH 10-11), but if the alkalinity is too strong or fluctuates greatly, it can cause the dye to hydrolyze prematurely, reducing the fixation rate.

In addition, dyeing depth and types of auxiliaries (such as leveling agents and chelating agents) can also alter the acid-base balance of the dye solution. Once there is a lack of effective pH control measures, even with the use of good dyes, it is difficult to avoid dyeing defects such as color difference, uneven color, and decreased fastness, which seriously affect product quality and customer satisfaction.

Buffer: The 'Stable Anchor Point' in the Staining Process

To solve this problem, buffering agents are commonly introduced in modern printing and dyeing processes to create a stable dyeing bath environment. By adding an appropriate amount of buffer system (such as acetic acid sodium acetate, phosphate, or high-performance organic buffer), pH fluctuations can be effectively suppressed throughout the dyeing process, ensuring that the binding of dye molecules to fibers is always in a good reaction window.

Especially in dynamic processes such as high-temperature and high-pressure dyeing, continuous pad dyeing, etc., the role of buffering agents is more critical. It can not only improve the success rate of dyeing, but also reduce rework and resource waste, lower water and energy consumption, and help enterprises achieve green production goals.

Product packaging

Hubei Xindesheng: Professional manufacturer of biological buffering agents

Hubei Xindesheng Material Technology Co., Ltd., as a professional manufacturer of biological buffering agents, not only focuses on the application of Tris, HEPES, MOPS and other buffering agents in the field of life sciences, but also has a keen insight into their enormous potential in industrial scenarios. The Tris, MOPS and other buffering agents produced by the company have high purity, good solubility, and stable batches, and have been successfully applied in multiple industrial fields such as textile printing and dyeing, water-based coatings, etc. We can provide customized buffer products and technical solutions according to customer needs, supporting different specifications of packaging and bulk supply, helping enterprises optimize processes, improve quality, and reduce costs.

Previous page

Previous page

News

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us