Packaging standards and quality control of chemiluminescence reagent luminol

Release time:

2025-08-04

In many fields such as chemical analysis, forensic science, environmental monitoring, etc., luminol, as a key chemiluminescence reagent, its stable performance directly affects the accuracy of experimental results. And this cannot be achieved without rigorous packaging standards and strict quality control systems, which complement each other and jointly safeguard Luminol. The packaging standards and quality control of chemiluminescence reagent luminol cover many aspects from packaging materials and specification design to raw materials, synthesis process, and finished product testing. Only by strictly controlling every step and following scientific and rigorous standards and processes can we ensure that luminol reagents serve various fields with stable performance.

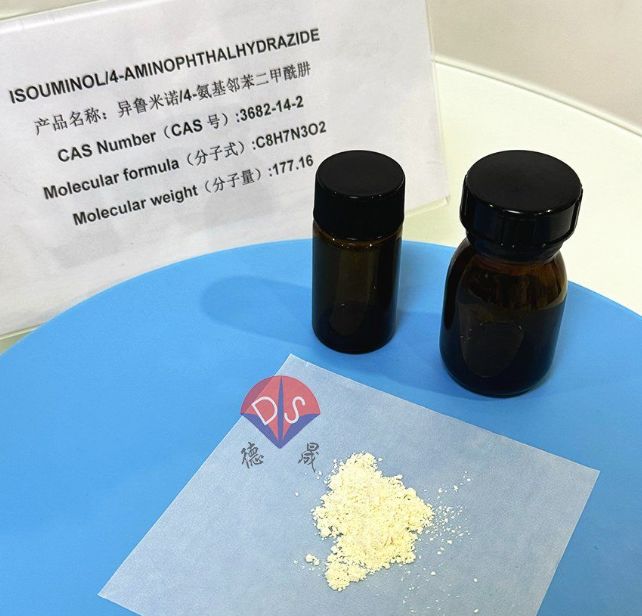

Luminol powder

Selection of Packaging Materials

1. Consideration of light avoidance: Luminol has chemiluminescence properties and is sensitive to light, especially the short wavelength parts of ultraviolet and visible light, which can easily trigger unwanted photochemical reactions, leading to reagent deterioration and decreased luminescence performance. Therefore, packaging materials need to have good light shielding properties. The common choice is brown glass bottles, which can block most of the light entering and reduce the impact of light on luminol. The glass material of the brown glass bottle itself has high stability and will not react chemically with luminol, ensuring that the chemical properties of the reagent are stable during storage.

2. Sealing requirements: Good sealing is the key to preventing luminol from getting damp, oxidized, and coming into contact with external impurities. The bottle cap needs to be able to tightly fit the bottle mouth, form a reliable seal, and not undergo any chemical reaction with luminol to ensure the purity of the reagent.

Quality control process

1. Raw material inspection: The quality of the starting materials for the synthesis of luminol directly determines the quality of the finished product. Strict purity testing is required for raw materials to ensure a purity of over 99%. At the same time, the detection of heavy metal content in raw materials, such as lead, mercury, cadmium, etc., these impurities may catalyze the decomposition reaction of luminol, making its luminescence performance unstable. By using atomic absorption spectroscopy (AAS) and other methods, the heavy metal content is strictly controlled to be below the specified limit, such as lead content not exceeding 10 ppm and mercury content not exceeding 5 ppm.

2. Synthesis process monitoring: Real time monitoring of reaction conditions is crucial in the synthesis of luminol. Accurately control key parameters such as reaction temperature and pH value through online pH meters, temperature sensors, and other devices. Monitor reaction progress and product purity, promptly identify and resolve issues such as side reactions and impurity generation, and ensure that the chemical structure and performance of each batch of luminol meet standards.

3. Finished product testing: The finished product luminol needs to undergo various inspections, starting with luminescence performance testing. Using a chemiluminescence analyzer, luminol is excited to generate a light signal, and compared with the standard curve to test whether its luminescence intensity, luminescence duration, and other indicators meet the standards, ensuring that it can stably and sensitively emit detectable light signals in practical applications. Next is purity testing, using HPLC and other methods to confirm that the purity of the finished product is not lower than the specified value. Generally, the purity of luminol at the chemical purity level is required to be above 98%. Only finished products that have passed various tests can enter the market, providing reliable guarantees for users.

Product packaging

As a research and development manufacturer of chemiluminescence reagents, Hubei Xindesheng is committed to improving the luminescence efficiency and stability of its products. In the production process, professional automated production equipment is equipped, and a standard quality control system is strictly followed. From careful selection of raw materials to layer by layer verification of packaging before leaving the factory, every step is striving for excellence. Not only does it provide small packages of high-purity reagents for research laboratories, but it can also be supplied in bulk. If you have purchasing intentions, please feel free to click on the website for consultation at any time!

Previous page

Previous page

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us