Hubei Xindesheng IVD Reagent Raw Material Production Process Requirements Standard

Release time:

2025-08-02

In the field of in vitro diagnostics (IVD), Hubei Xindesheng, as a professional IVD reagent raw material manufacturer, has established strict production process requirements and standards. Every link from raw material procurement to finished product delivery is strictly controlled to ensure the quality and stability of IVD reagent raw materials, providing reliable product support for the in vitro diagnostics industry.

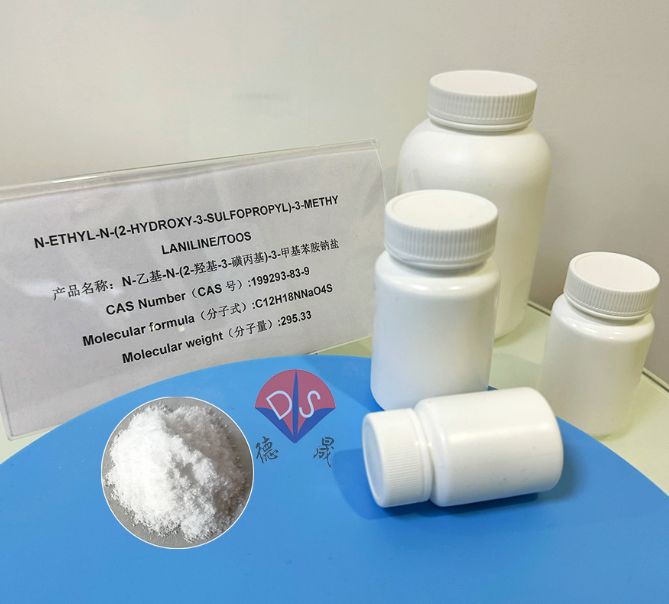

(Chromogenic substrate TOOS)

Production environment requirements

Divide into different areas according to different production processes and product requirements. For example, for the production area of highly sensitive chemiluminescence reagent raw materials, cleanliness is required. Equipped with professional temperature and humidity control equipment and ventilation systems, control temperature, humidity, and air circulation according to the production process requirements of different products.

Production equipment management

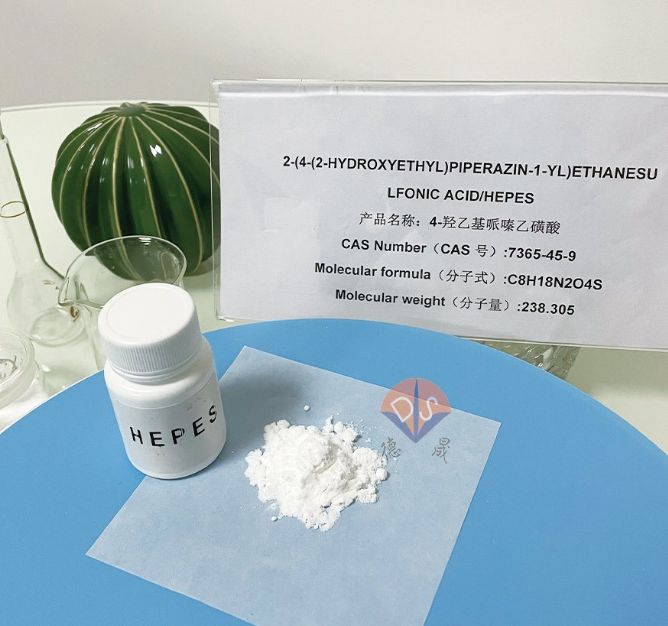

1. Equipment selection and procurement: Select stable and reliable production equipment and instruments according to the needs of the production process. In the synthesis reaction of biological buffering agents, the use of high-precision automated reaction vessels can accurately control the reaction temperature, stirring speed, and reaction time, ensuring the consistency and stability of the reaction.

2. Equipment maintenance and calibration: Establish a comprehensive equipment maintenance system and calibration plan, regularly maintain, upkeep, and calibrate production equipment to ensure its normal operation and measurement accuracy. For example, for analytical and testing equipment such as liquid chromatography and gas chromatography, calibration and performance verification should be conducted once a month to ensure that the test results are not disturbed.

process control

1. Standardized operating procedures: For each type of IVD reagent raw material, a detailed standardized production operating procedure is developed to clarify the various links and operating steps in the production process, including raw material feeding sequence, reaction condition control, intermediate product detection, product refinement, etc.

2. Process quality monitoring: Set up multiple quality monitoring points during the production process to monitor and control key process parameters and intermediate product quality in real time. During the production process of chromogenic substrates, key parameters such as pH value, temperature, and reaction time of the reaction solution should be monitored online. Once abnormalities are detected, they should be adjusted in a timely manner to ensure the stability of product quality.

quality inspection

1. Finished product quality inspection: Each batch of products needs to undergo strict quality inspection before leaving the factory, covering multiple aspects such as appearance, characteristics, purity, content, activity, stability, etc. For example, for blood collection tube additive products, in addition to testing their anticoagulant or procoagulant effects, it is also necessary to test their effects on blood cells and compatibility with other reagents.

2. Product factory audit: Only products that have undergone quality inspection and all indicators meet the standard requirements can submit a factory application. The quality department is responsible for the audit, which includes production process records, inspection reports, deviation handling, etc., to ensure that product quality meets requirements and is traceable.

Personnel training and management

Professional skills training: Regularly organize employees to participate in professional skills training, including knowledge and skills training in instrument operation, quality control, etc., to continuously improve employees' professional quality and business ability. For example, inviting university teachers to give lectures and training, introducing the latest IVD reagent raw material production technology and quality control methods.

Quality awareness cultivation: Strengthen the quality awareness education of employees, through organizing quality month activities, internal quality case sharing and other forms, so that employees fully realize the importance of product quality, and ensure strict compliance with quality standards and operating procedures in the production process.

As a research and development manufacturer of IVD reagent raw materials, Hubei Xindesheng has gradually established a good reputation in the industry with its profound technical accumulation and innovative spirit. The R&D team continuously explores new technologies and optimizes product performance. Production strictly follows standards, from raw material control to finished product testing, to ensure stable quality of each batch of products. If you have purchasing intentions, please feel free to contact us at any time!

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us