Focusing on chemiluminescence reagent raw materials, can we establish a firm foothold in the IVD industry

Release time:

2025-07-30

In the current booming development of in vitro diagnostics (IVD) industry, chemiluminescence technology has become one of the mainstream clinical testing technologies with its advantages of high sensitivity, high specificity, and high degree of automation, occupying a considerable market share in the IVD industry. For example, in the segmented market of diagnostic antigen antibodies, chemiluminescence occupies 52.29% of the market share. As the core component of chemiluminescence detection systems, the importance of chemiluminescence reagent raw materials is self-evident. So, can it stand firm in the fiercely competitive IVD industry?

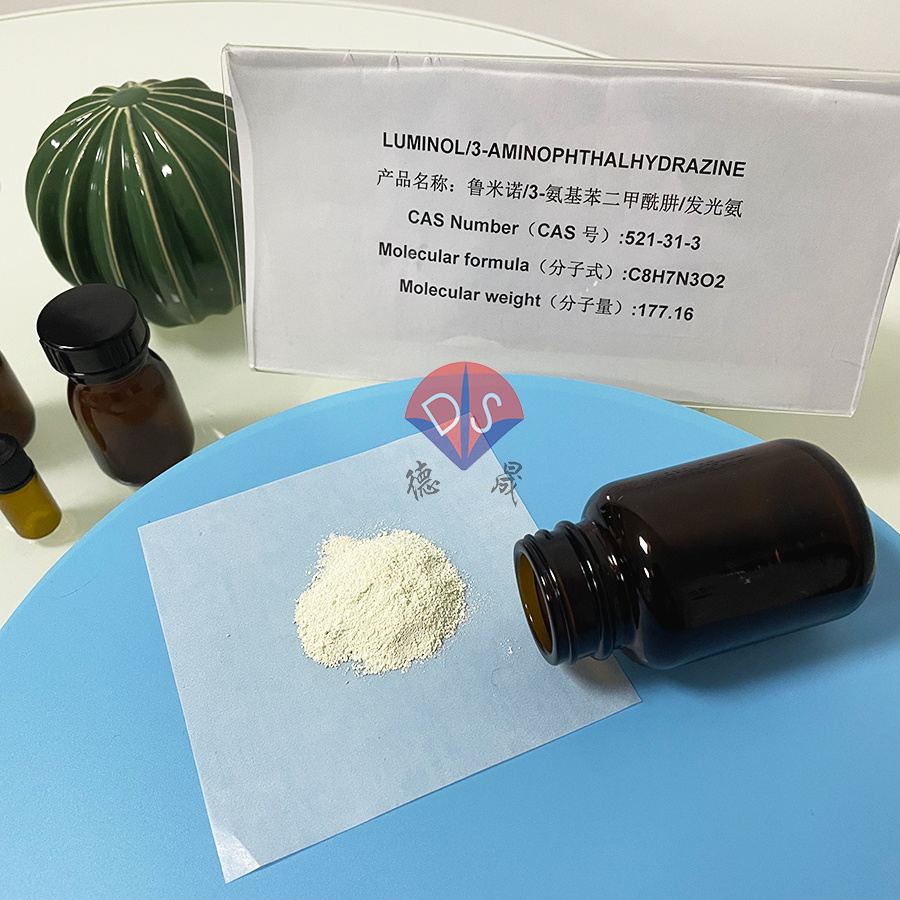

(Chemiluminescence reagent luminol)

The current situation of chemiluminescence reagent raw materials in the IVD industry

1. Key raw materials rely on imports

At present, some key raw materials for chemiluminescence reagents in China, such as magnetic beads, high-quality antigen antibodies, and some enzymes, are highly dependent on imports. Taking magnetic beads as an example, they play a crucial role as the cornerstone of chemiluminescence reagents in processes such as separation, enrichment, and signal amplification. However, over 95% of the domestic market demand is monopolized by imported brands. In terms of antigen and antibody, although domestic enterprises are constantly developing, they still cannot meet all the clinical application needs in some specific antigen and antibody fields, and many enterprises have to import from abroad.

2. Domestic enterprises actively layout

Despite facing the dilemma of import dependence, many domestic enterprises have keenly realized the potential of the chemiluminescence reagent raw material market and have increased their investment and layout in this field. Some companies have made breakthroughs in the production technology of certain raw materials through independent research and development. For example, Hubei Xindesheng Company has been deeply involved in the field of luminescent reagent raw materials for many years. Its flagship product, the acridine ester series, continuously optimizes its synthesis process and purification technology to improve product purity and stability. In the production process, Xindesheng strictly controls every step, from raw material screening to finished product testing, all following standard procedures. With reliable product quality, its acridine ester raw materials have been adopted by multiple domestic chemiluminescence reagent manufacturers and successfully applied in the production of marker detection kits and other products. Some enterprises have integrated resources through mergers and acquisitions, cooperation, and other means to enhance their strength in raw material research and production, gradually building a system of independent supply of raw materials.

Challenges faced by raw materials for chemiluminescence reagents

1. High technical threshold

The research and production of chemiluminescence reagent raw materials involve multiple disciplines such as immunology, biochemistry, proteomics, and polymer nanomaterials, with a high degree of technical complexity. Taking the preparation of high-quality monoclonal antibodies as an example, it requires a series of delicate and difficult steps such as cell fusion, screening, cloning culture, etc., which have high requirements for experimental equipment, operators' technical level, and research and development environment.

2. Quality stability is difficult to guarantee

Due to numerous influencing factors in the production process of raw materials, such as batch differences in raw materials, subtle fluctuations in production equipment, and changes in environmental conditions, the quality of raw materials may fluctuate. Even the same batch of raw materials produced by the same enterprise may have quality differences, which poses a major challenge to the product quality control of reagent production enterprises.

3. Intense market competition

The IVD industry has a broad market and attracts numerous participants, including the market for chemiluminescence reagent raw materials. On the one hand, foreign giants dominate the market with their long-term accumulated technological advantages, brand influence, and well-established sales channels, creating significant competitive pressure on domestic enterprises. These enterprises often have advanced research and development platforms and large-scale production bases, which can quickly respond to market demand and launch high-quality new products. On the other hand, numerous domestic enterprises have flooded into this field, making market competition increasingly fierce. In the process of competition, some companies may adopt a low price competition strategy in order to compete for market share, which not only compresses their profit margins, but also may lead to uneven product quality in the market, which is not conducive to the healthy development of the industry.

Advantages and Development Opportunities of Chemiluminescence Reagent Raw Materials

With the rapid development of the domestic IVD industry and the increasing emphasis on the independent and controllable development of the biopharmaceutical industry, the demand for domestic substitution of chemiluminescence reagent raw materials is becoming increasingly urgent. At present, the localization rate of chemiluminescence is less than 30%, which means that domestic enterprises have huge development space in this field. The localization substitution of raw materials can not only reduce the production cost of reagents and improve the competitiveness of domestic enterprises in overseas markets, but also ensure the stability of the supply chain and reduce supply risks caused by changes in the situation. Driven by policy support and market demand, more and more domestic enterprises are expected to make breakthroughs in the field of chemiluminescence reagent raw materials and gradually achieve import substitution.

(Luminescent reagent acridine ester)

As a supplier of luminescent reagent raw materials, Hubei Xindesheng Company has deep expertise in the production of acridine ester luminescent reagent raw materials. Its acridine ester products undergo multiple fine purification processes, strictly controlling product purity and impurity content, which can reduce background interference and improve detection signal strength. The company has established a comprehensive quality control system, with strict testing standards set at every stage from raw material procurement, synthesis reaction to finished product inspection, ensuring stable product performance and establishing long-term cooperation with numerous domestic and foreign production enterprises. If you have any purchasing needs, please feel free to contact us at any time!

Previous page

Previous page

News

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us