The Importance of Stable Supply Chain of IVD Reagent Raw Materials

Release time:

2025-06-02

In the current booming industry of in vitro diagnostics (IVD), IVD reagent raw materials serve as the foundation for diagnostic reagent production. The stability of their supply chain has a profound impact on the healthy development of the industry, the survival and operation of enterprises, and clinical diagnosis. A stable supply chain of IVD reagent raw materials is the cornerstone of industry development, playing an irreplaceable role in ensuring the accuracy and timeliness of diagnosis, maintaining enterprise production order, and promoting industry innovation and upgrading.

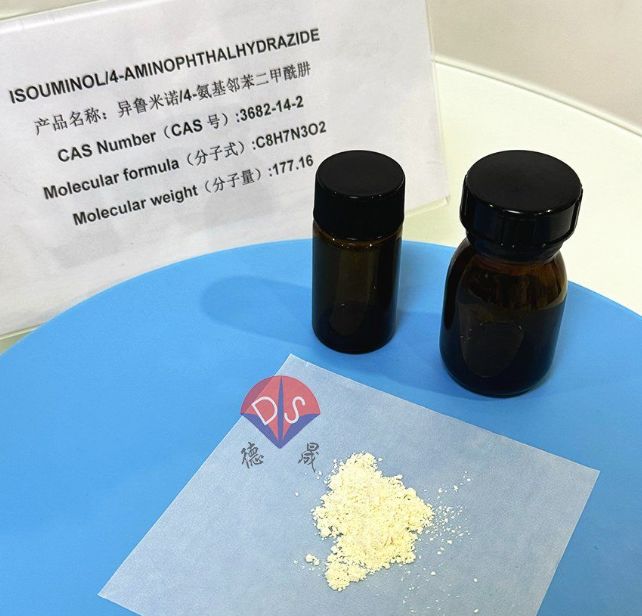

(IVD luminescent reagent isoluminol)

Ensure testing results

1. Ensuring consistency in raw material quality: A stable supply chain means that IVD reagent manufacturers can continuously obtain high-quality raw materials. When there are fluctuations in the raw material supply chain, frequent changes in suppliers, or uneven quality of raw material batches, it can lead to unstable performance of the diagnostic reagents produced. In chemiluminescent immunoassay reagents, if the batch differences of luminescent raw materials are too large, it may cause inconsistent detection signal intensity, thereby affecting the accurate determination of the concentration of target substances in the sample and leading to deviation in the detection results. A stable supply chain can ensure that the quality of raw materials from the same batch and different batches remains at a high and consistent level, providing a guarantee for the production of diagnostic reagents with stable performance and accurate and reliable testing results, so that clinical testing results can truly reflect the patient's condition.

2. Reduce detection errors caused by raw material issues: An unstable supply chain can easily lead to problems such as raw material shortages and substandard quality, which directly affect the production and use of diagnostic reagents. If the enterprise is forced to temporarily replace raw materials due to the interruption of raw material supply, the new raw materials may not match the original production process, or there may be quality hazards, resulting in testing errors. A stable supply chain can prevent such situations from occurring, ensuring that enterprises produce according to established production processes and quality standards, and reducing detection errors caused by raw material problems from the source.

Maintain the normal order of enterprise production and operation

1. Avoiding production interruptions and cost increases: The production plan of IVD reagent manufacturing enterprises relies on stable raw material supply. Once there are problems in the supply chain, such as raw material suppliers ceasing production or transportation disruptions, it will lead to production interruptions for the enterprise. In order to resume production, companies may need to urgently seek alternative raw materials, which not only increases procurement costs, but may also lead to production process adjustments, unstable product quality, and other issues due to raw material replacement, further increasing production costs. A stable supply chain can enable enterprises to produce in an orderly manner according to production plans, arrange inventory reasonably, reduce additional costs caused by production interruptions and emergency procurement of raw materials, and improve the production efficiency and economic benefits of enterprises.

2. Ensuring corporate reputation and market competitiveness: In the fiercely competitive IVD market, stable product supply is the key to winning customer trust and market share for enterprises. If a company is unable to deliver products on time or experiences fluctuations in product quality due to an unstable raw material supply chain, it will seriously damage the company's reputation and lead to customer loss. On the contrary, enterprises with stable raw material supply chains can provide products to customers on time, with quality and quantity, establish a good corporate image, and enhance customers' trust and loyalty to the enterprise. A stable supply chain also enables enterprises to better respond to changes in market demand, adjust production plans in a timely manner, maintain market competitiveness, and occupy a favorable position in the industry.

Hubei Xindesheng Material Technology Co., Ltd. has demonstrated reliable strength in ensuring the stability of the IVD reagent raw material supply chain. The company has been deeply involved in the field of IVD reagent raw materials for many years and has established a comprehensive supply chain management system. In the process of raw material procurement, we have established long-term and stable cooperative relationships with numerous enterprises. Through strict supplier screening and evaluation mechanisms, we ensure the reliable quality and stable supply of the purchased raw materials.

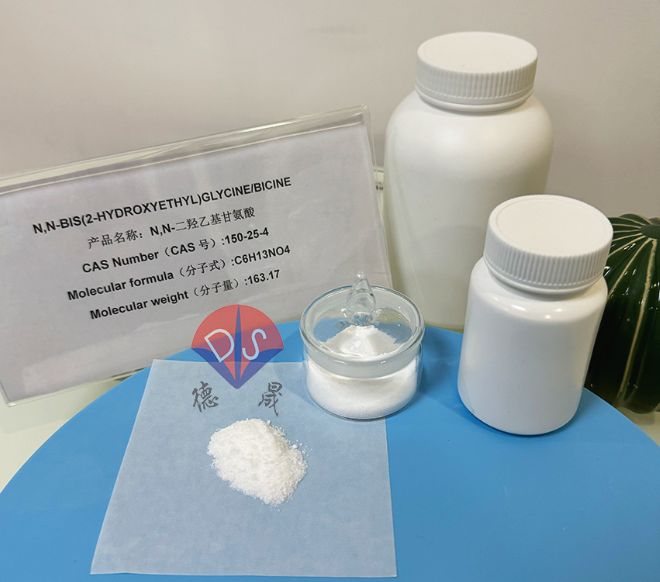

(Bicine biological buffer)

Xindesheng has strong production capacity, advanced production equipment, and a professional production team. It can adjust production plans in a timely manner according to market demand to ensure stable supply of products. The company has also established a reasonable inventory management system to ensure the supply of raw materials and products while reducing inventory costs. With a high emphasis on supply chain stability and excellent management capabilities, Hubei Xindesheng provides reliable raw material guarantees for IVD reagent production enterprises and has become a trusted partner in the industry. If you have any purchasing needs, please feel free to contact us at any time!

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us