What are the improvement measures for the production process of IVD chemical reagents raw materials

Release time:

2025-05-22

In the rapidly developing field of in vitro diagnostics (IVD), the quality and performance of IVD chemical reagents play a crucial role in the accuracy and reliability of diagnostic results. As the core factor determining the quality of raw materials, the optimization and improvement of production processes are crucial. Through reasonable improvement measures, not only can product quality be improved and production costs be reduced, but also the competitiveness of enterprises in the market can be enhanced. The following will explore improvement measures for the production process of IVD chemical reagent raw materials from multiple aspects.

(MOPSO buffer raw material)

Optimize reaction conditions and parameter control

1. Accurately regulating reaction temperature and time: In the synthesis process of IVD chemical reagents, reaction temperature and time have a significant impact on product quality. Different chemical reactions need to be carried out within specific temperature ranges, and temperatures that are too high or too low can lead to side reactions, affecting the purity and performance of the raw materials. In the production of certain enzymatic reaction materials, slight changes in temperature may alter the activity and selectivity of enzymes, thereby affecting the yield and quality of reaction products. Therefore, by introducing a high-precision temperature control system, real-time monitoring and accurate adjustment of reaction temperature, and optimizing reaction time based on reaction characteristics, it is possible to ensure that the reaction proceeds under ideal conditions and improve the stability of product quality.

2. Optimizing the ratio of reaction materials: A reasonable ratio of reaction materials is the key to improving the efficiency and quality of raw material production. Conduct in-depth research and optimization on the proportion of various materials in the reaction process, and determine the ideal material ratio scheme through experiments and data analysis. In some organic synthesis reactions, improper proportions of raw materials may lead to incomplete reactions or excessive impurities. By adjusting the material ratio, not only can the conversion rate and selectivity of the reaction be improved, but also the waste of raw materials can be reduced and production costs can be lowered.

Upgrade production equipment and technology

1. Automated production equipment: Traditional manual production methods have problems such as low efficiency, large errors, and unstable quality. The introduction of automated production equipment can solve these drawbacks. Automated production lines can achieve accurate measurement, transportation, mixing of raw materials, and automated control of reaction processes, reducing human interference in the production process. In the production of chemiluminescence reagent raw materials, automated equipment can accurately control the preparation ratio and reaction conditions of reagents, improving product consistency and stability. At the same time, automated production can improve production efficiency, reduce labor intensity, and meet the large-scale demand for products in the market.

2. Adopting advanced separation and purification technology: Separation and purification are important steps in the production of IVD chemical reagents, directly affecting the purity and quality of the products. Traditional separation and purification methods such as filtration and distillation have problems such as low efficiency and poor separation efficiency. Adopting advanced separation and purification technologies, such as chromatographic separation techniques (including liquid chromatography, gas chromatography, etc.), membrane separation techniques, etc., can remove impurities and improve product purity.

Strengthen quality control in the production process

1. Establishing a real-time monitoring system: In the production process, establishing a real-time monitoring system can timely detect and solve problems, ensuring product quality. By installing sensors and monitoring equipment, key parameters such as temperature, pressure, pH value, and material concentration during the reaction process can be monitored in real-time. Once the parameters are abnormal, the system can immediately issue an alarm and automatically take corresponding adjustment measures. At the same time, real-time monitoring of temperature, humidity, cleanliness, and other factors in the production environment is carried out to ensure that the production process is carried out in a suitable environment and prevent external factors from affecting product quality.

2. Implement standardized operating procedures: Develop detailed and standardized standard operating procedures (SOPs) to clearly define every aspect of the production process. From the acceptance, storage, and weighing of raw materials, to the control of reaction processes, separation and purification of products, packaging, etc., there are strict operating standards and requirements. Strengthen training for production personnel to familiarize them with and strictly adhere to SOPs, ensuring consistent production processes for each batch of products. By implementing standardized operating procedures, it is possible to reduce operational errors and improve the stability of product quality.

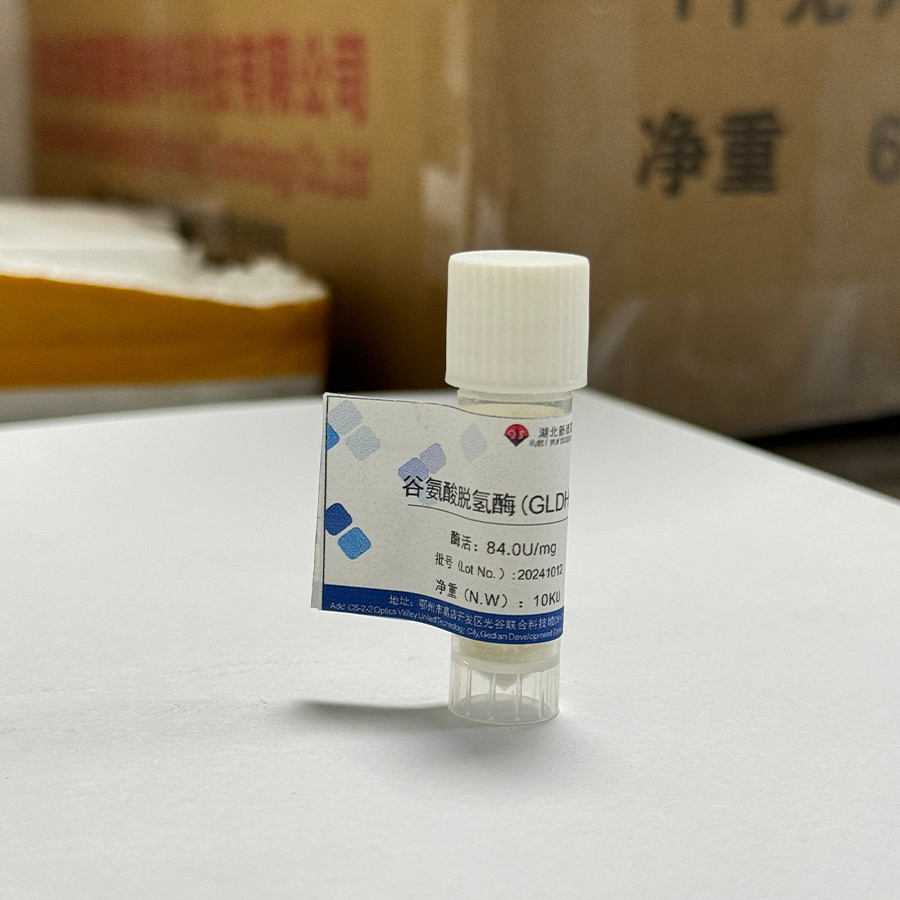

In terms of improving the production process of IVD chemical reagents, Hubei Xindesheng Company has accumulated rich experience and achieved significant results. Since its establishment, the company has always focused on optimizing and innovating production processes, continuously introducing advanced production equipment and technology. Through accurate reaction condition control, advanced separation and purification technology, and strict quality control system, we ensure the stable and reliable quality of IVD chemical reagent raw materials produced. With unremitting efforts in improving production processes, New Desheng's raw materials such as biological buffering agents, color reagents, luminescent reagents, enzyme preparations, etc. have won the trust of many customers in the market. If you have any purchasing needs, please feel free to contact us at any time!

News

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us