What are the industrial chains of IVD reagent industry divided into? It's clear at a glance

Release time:

2025-05-29

In the current booming development of the medical and health industry, the in vitro diagnostic (IVD) reagent industry, as an important support for accurate diagnosis, has attracted much attention to the composition and development of its industrial chain. The IVD reagent industry chain covers three main links: upstream raw materials, midstream diagnostic products, and downstream application ends. Each link works closely together to promote the development of the industry. A clear understanding of the structure and characteristics of the industrial chain helps to grasp industry trends and promote the development of enterprises.

Upstream raw materials: the foundation of industry development

Upstream raw materials are the foundation of the IVD reagent industry, and their quality and supply stability directly affect the performance and production of midstream diagnostic products. The upstream raw materials mainly include three categories: core reaction system raw materials, signal system raw materials, and reaction system carriers.

(1) Core reaction system raw materials: Core reaction system raw materials play a crucial role in the detection process of IVD reagents, determining the specificity and accuracy of the detection. This type of raw material includes biologically active substances such as antigens, antibodies, enzymes, nucleic acids, as well as various chemical reagents. In immunodiagnostic reagents, the quality of antigens and antibodies directly affects the sensitivity and specificity of the detection results; In molecular diagnostic reagents, the performance of nucleic acid probes and polymerases is crucial for the accuracy and efficiency of detection.

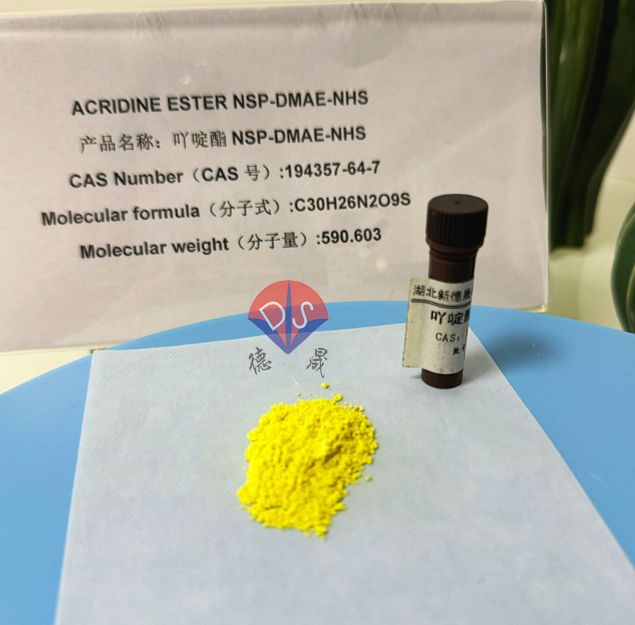

(2) Signal system raw materials: Signal system raw materials are used to amplify and convert the signals generated by detection reactions for easy detection and analysis. Common signal system raw materials include chemiluminescent agents, chromogenic substrates, fluorescent markers, etc. In chemiluminescence immunoassay, chemiluminescence agents can generate a light signal during the reaction process, and the content of the detected substance can be determined by detecting the intensity of the light signal.

(3) Reaction system carrier: Reaction system carriers provide a stable environment for detecting reactions, commonly including microplates, magnetic beads, chips, etc.

Midstream diagnostic products: the core link of the industry

Midstream diagnostic products are the core of the IVD reagent industry, mainly referring to the reagents and instruments used for in vitro testing and diagnosis. The research and development, production, and sales of diagnostic products directly face market demand and serve as a bridge connecting upstream raw materials and downstream application ends.

(1) Diagnostic reagents: There are many types of diagnostic reagents, which can be divided into immunological diagnostic reagents, molecular diagnostic reagents, biochemical diagnostic reagents, microbiological diagnostic reagents, etc. according to different detection principles and methods. Immunodiagnostic reagents are currently one of the largest types of reagents in the market, widely used in fields such as infectious disease detection and tumor marker detection; Molecular diagnostic reagents have advantages in pathogen detection, genetic testing, and genetic disease diagnosis due to their high sensitivity and specificity; Biochemical diagnostic reagents are mainly used for the detection of clinical biochemical indicators, such as blood glucose, blood lipids, liver function, kidney function, etc. Different types of diagnostic reagents have their own characteristics and requirements in research and development, production, and quality control.

(2) Diagnostic instruments: Diagnostic instruments and diagnostic reagents complement each other to jointly complete in vitro diagnostic testing. Common diagnostic instruments include chemiluminescence immunoassay analyzer, nucleic acid amplification analyzer, fully automatic biochemical analyzer, flow cytometer, etc. The performance of diagnostic instruments directly affects the speed, accuracy, and degree of automation of detection. The chemiluminescence immunoassay analyzer can achieve automated detection, with advantages such as fast detection speed, high sensitivity, and strong specificity.

Downstream application end: embodiment of industry value

1. The downstream application end is a reflection of the value of the IVD reagent industry, mainly including medical institutions, third-party diagnostic laboratories, and individual consumers.

Medical institutions: Diagnostic institutions are the main application sites for IVD reagents, including hospitals, health centers, clinics, etc. In clinical diagnosis, IVD reagents and instruments are widely used in screening, diagnosis, monitoring, and prognosis evaluation of diseases.

2. Third party diagnostic laboratory: As an independent medical testing institution, third-party diagnostic laboratories have advantages such as complete testing items, high degree of specialization, and flexible services. They reduce testing costs and provide testing services to medical institutions, physical examination centers, pharmaceutical companies, etc. through centralized procurement and large-scale operation.

3. Individual consumers: With the improvement of people's health awareness and the continuous development of home diagnostic products, the demand for IVD reagents among individual consumers is gradually increasing. Home blood glucose test strips, pregnancy testing strips, infectious disease rapid detection reagents and other products are increasingly favored by consumers. Individual consumers can conduct simple self tests at home through these home diagnostic products to timely understand their health status.

(Chromogenic substrate MAOS)

In the IVD reagent industry chain, Hubei Xindesheng focuses on the upstream raw material field, especially the research and production of signal system raw materials and some core reaction system raw materials. Since its establishment, the company has continuously improved product quality and performance with a professional R&D team and advanced production technology. In terms of signal system raw materials such as chemiluminescence agents and chromogenic substrates, Xindesheng has a rich product line and mature production processes. The product quality is stable and reliable, which can meet the needs of midstream diagnostic product production enterprises. If you have any purchasing needs, please feel free to contact us at any time!

News

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us