Suggestions from Hubei Xindesheng for Large scale IVD Raw Material Procurement Enterprises

Release time:

2025-11-08

In the in vitro diagnostics (IVD) industry, enterprises that procure raw materials on a large scale bear the responsibility of ensuring stable product quality, controllable costs, and smooth supply chains. As a member deeply involved in the field of IVD raw materials, Hubei Xindesheng provides various suggestions based on rich industry experience to help these enterprises optimize their procurement strategies and enhance their overall competitiveness in complex and changing market environments.

Rigorously screening suppliers and building stable cooperation

1. Evaluate production and research and development capabilities

Production capacity is directly related to whether suppliers can meet the needs of large-scale procurement for enterprises. Enterprises need to assess suppliers' capacity planning, advanced equipment, and professional competence of production personnel. Taking enzyme raw material production as an example, advanced fermentation equipment and automated purification production lines can ensure the stability of product yield and quality. At the same time, research and development capabilities cannot be ignored. Suppliers with continuous research and development capabilities can provide enterprises with better performance raw material upgrade solutions based on market demand and technological development, such as developing more specific antibody raw materials to improve the detection accuracy of IVD reagents.

2. Establish a supplier evaluation system

Establish a scientific supplier evaluation system to regularly evaluate suppliers from dimensions such as product quality, timely delivery, reasonable price, and after-sales service. For example, for product quality, the quality pass rate can be calculated by conducting random inspections on each batch of raw materials to test key indicators such as purity and activity; The timeliness of delivery is measured based on the on-time rate of the order delivery cycle. Based on the evaluation results, provide more cooperation opportunities to suppliers with good performance.

Control procurement costs and achieve efficiency improvement

1. Analyze market price trends

The market price of IVD raw materials is influenced by various factors, such as raw material supply and technological innovation. Enterprises should arrange professional personnel to closely monitor market trends, collect raw material price data, and construct price prediction models through data analysis tools. For example, for chemical reagent raw materials that are greatly affected by fluctuations in upstream chemical raw material prices, future price trends can be predicted by analyzing the market trends of chemical raw materials, industry capacity expansion or contraction, in order to increase procurement volume appropriately during price troughs and reduce procurement costs.

2. Flexibly apply procurement strategies

By leveraging the advantage of large-scale procurement, negotiate bulk purchase discounts with suppliers. Enterprises can determine a reasonable batch procurement scale based on their own inventory management capabilities and production plans. If a large quantity of buffer raw materials are purchased at once, a price discount of 10% -15% can be obtained while ensuring quality.

Sign long-term cooperation contracts with reliable suppliers to lock in prices and supply volumes for a specific period of time. Price adjustment clauses can be included in the contract to adjust prices reasonably based on changes in key market factors, which not only ensures a reasonable profit margin for suppliers, but also enables enterprises to avoid the risk of significant price increases.

Pay attention to quality control and ensure product quality

(1) Participate in the construction of supplier quality control system

Enterprises should actively communicate with suppliers and participate in the construction and optimization of their quality control system. For example, providing suggestions on raw material quality standards and testing methods to suppliers, and assisting them in improving their internal quality testing processes; Require suppliers to regularly maintain and calibrate production equipment, and provide relevant records to ensure stable equipment operation and compliance with quality requirements during the production process. At the same time, enterprises can conduct regular quality audits of suppliers, timely propose rectification suggestions for problems found, and jointly improve the stability of raw material quality.

(2) Strengthen the testing of incoming raw materials

Establish a strict system for testing incoming raw materials, equipped with professional testing equipment and personnel. Inspect each batch of IVD raw materials according to established quality standards. For biological raw materials, in addition to testing conventional activity and purity indicators, microbial limit and endotoxin testing are also required; For chemical raw materials, key indicators such as acidity, alkalinity, and impurity content should be tested. Only qualified raw materials can enter the production process, ensuring the quality of IVD reagents from the source.

In addition, it is important to accumulate potential supplier resources and establish connections with multiple suppliers. Even during normal procurement periods, a small amount of raw materials can be purchased from backup suppliers for quality verification and cooperation. When the main supplier encounters supply issues, it can quickly switch to a backup supplier to ensure production continuity.

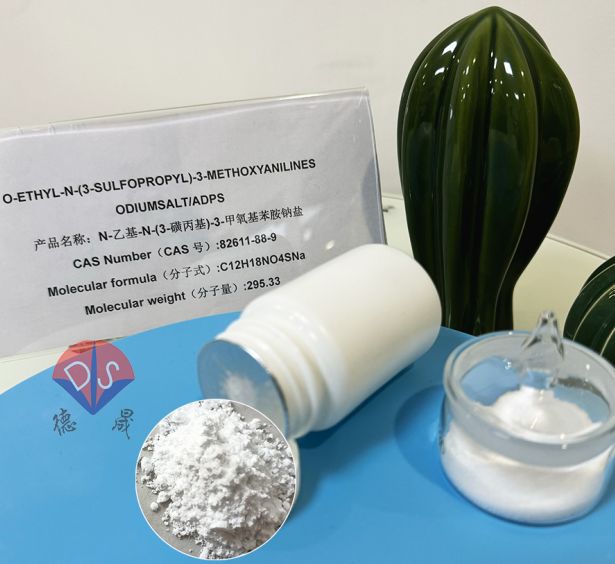

Product packaging

Enterprises engaged in large-scale procurement of IVD raw materials need to comprehensively consider multiple aspects such as supplier management, cost control, inventory optimization, quality assurance, and risk response during the procurement process. Hubei Xindesheng Company, as an upstream IVD reagent raw material manufacturer, can supply various types of raw materials such as biological buffering agents, luminescent reagents, chromogenic substrates, etc., suitable for biochemical diagnosis, chemiluminescence, molecular diagnosis and other detection systems. Relying on standardized production processes and strict quality control systems, we ensure the stability of raw material batches and support large-scale procurement from gram to ton levels. Provide customized services, adjust raw material purity and specifications according to needs, and attach complete quality inspection reports. If you have any purchasing needs, please feel free to contact us at any time!

Previous page

Previous page

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us