Desheng's answer: How IVD reagents can reduce upstream supply chain risks

Release time:

2025-10-24

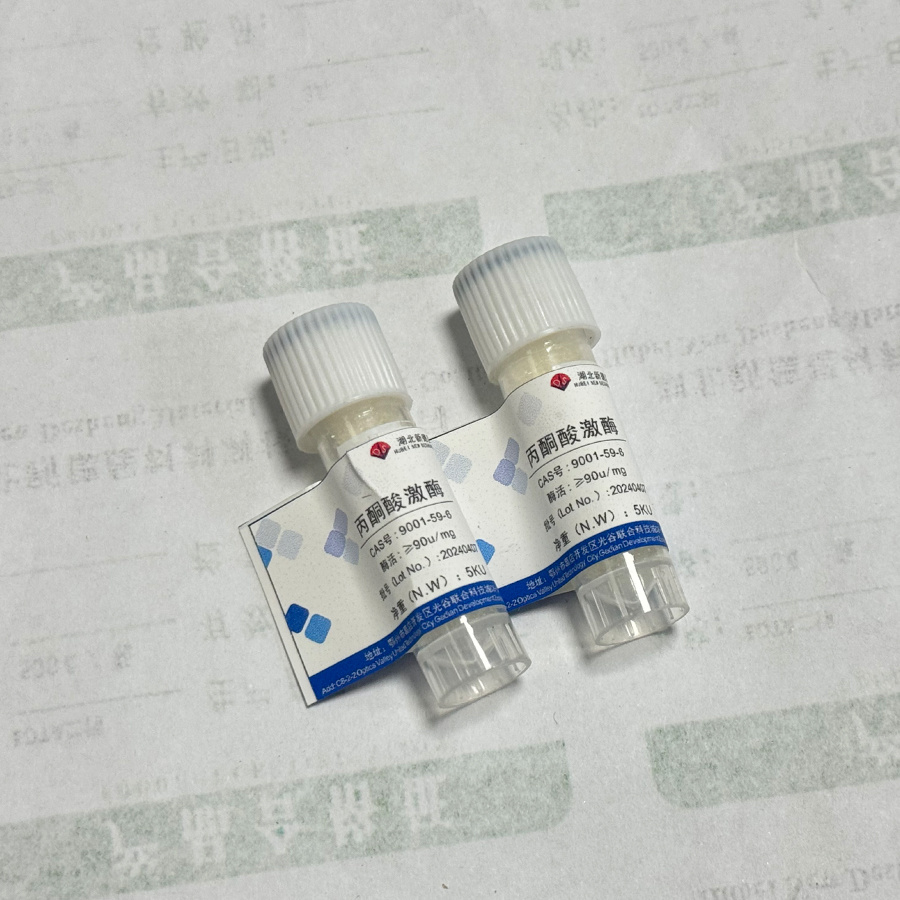

Against the backdrop of rapid development in the IVD industry, the stability of the upstream supply chain is directly related to the continuity of reagent production and product quality. Any interruption or fluctuation in any link from raw material procurement to production delivery may trigger a chain reaction, affecting terminal testing services. As an upstream IVD reagent raw material manufacturer, Desheng combines industry practice and technical experience to analyze feasible paths to reduce supply chain risks from multiple perspectives.

Establish a diversified raw material supply system to reduce single dependence

1. Multi source layout of core raw materials

The production of IVD reagents relies on multiple key raw materials, such as biological buffering agents, luminescent reagents, enzyme preparations, etc. Single supplier dependence may lead to supply interruptions due to insufficient production capacity, unexpected accidents, etc. It is recommended to establish at least two qualified suppliers for core raw materials, forming a dual track model of "main supplier+alternative supplier". For example, for the acridine ester raw material in chemiluminescence reagents, a main supplier can be selected to ensure regular supply, and alternative suppliers can be introduced through quality verification. When the main supplier encounters problems, alternative suppliers can start supplying within 1-2 weeks to control the risk of supply interruption. The characteristics of raw materials from different suppliers may vary, and standardization verification is required to ensure compatibility of multiple sources of raw materials. When providing Tris buffer for downstream enterprises, Desheng will provide detailed quality parameters (such as purity, pH stability, impurity content) to help establish quality comparison standards for multi-source raw materials, ensuring that the performance of reagents is not affected after replacing suppliers.

2. Reasonable combination of domestic and imported raw materials

Some raw materials have long relied on imports and are greatly affected by factors such as logistics and trade policies. Enterprises can gradually reduce their dependence on imports through domestic substitution, and prioritize the selection of domestically produced products that have passed quality verification for non core raw materials, while adopting a "import+domestic" combination model for core raw materials. Domestic upstream enterprises such as Desheng have achieved domestic substitution of various IVD raw materials through process upgrades, with performance comparable to imported products, providing possibilities for supply chain diversification.

Strengthen supply chain quality management and control risks from the source

1. Establish strict supplier admission standards

The quality of upstream raw materials directly determines the performance of IVD reagents, and a scientific supplier admission system needs to be established, covering dimensions such as production qualifications, quality systems, production capacity, and research and development capabilities. During the audit process, not only should written materials from suppliers be examined, but on-site audits should also be conducted, with a focus on the quality control aspects of the raw material production process (such as purification technology, aseptic treatment, batch stability testing).

2. Improve the raw material storage inspection process

Strict inspection is required after the arrival of raw materials to prevent unqualified materials from entering the production process. The inspection items should include key indicators such as appearance, purity, pH value, and impurity content, and functional testing should be conducted when necessary. Establish a raw material quality traceability system to record the inspection data and usage direction of each batch of raw materials. When quality problems occur in end products, they can be quickly traced back to the raw material batch, shortening the time for problem investigation.

Reducing the upstream supply chain risk of IVD reagents is a systematic project that requires efforts from multiple aspects such as supply layout, quality control, and inventory management. By diversifying the supply system to diversify risks, ensuring strict quality control of raw materials, dynamically balancing supply and demand through inventory, and deepening cooperation, enterprises can guarantee production continuity in complex and ever-changing market environments. Upstream raw material manufacturers such as Desheng provide stable and reliable raw material support to downstream enterprises through technological upgrades and service optimization, becoming an important force in supply chain risk prevention and control. At present, Xindesheng, as an upstream reagent supplier, has biological buffering agents, colorimetric reagents, luminescent reagents, and enzyme substrate raw materials available for sale in stock at affordable prices, providing customized services and technical support. If you have any purchasing needs, please feel free to contact us at any time!

News

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us