90% of IVD companies have overlooked it! Three dimensions determine the success or failure of a new product

Release time:

2025-05-01

In the IVD industry, the success rate of new product development often depends on three key dimensions: timing, location, and special understanding. However, 90% of practitioners only focus on technology or market, neglecting deeper risk prediction and resource integration.

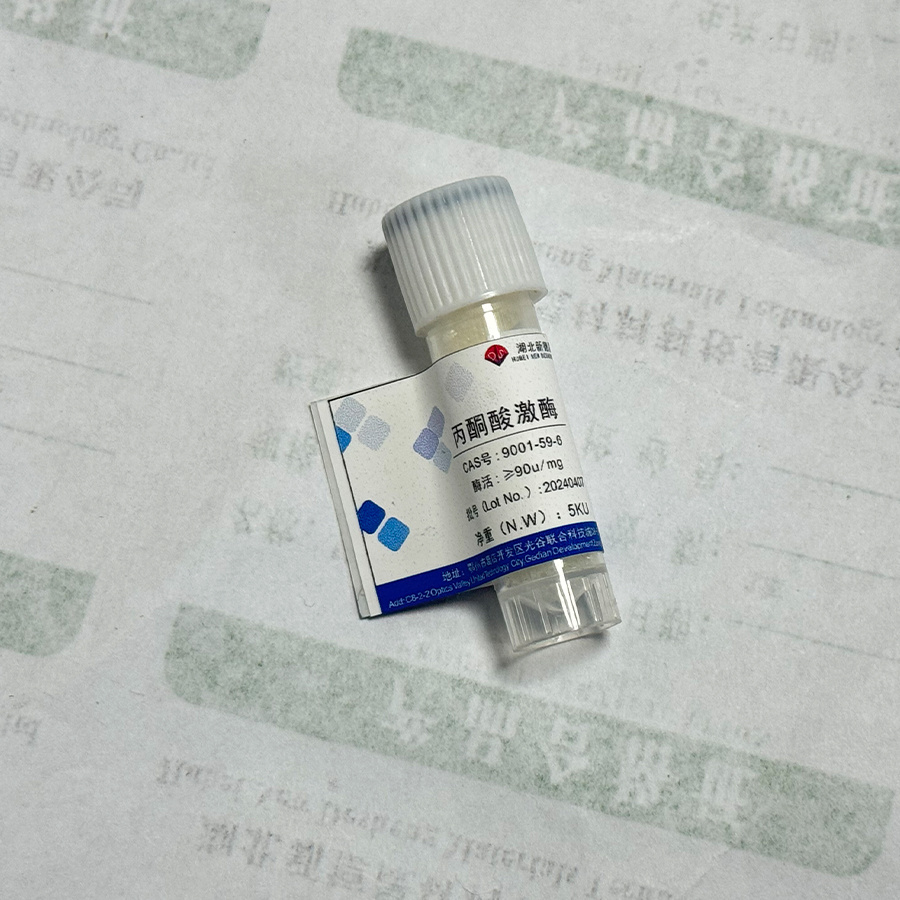

Pyruvate kinase

1. Timing: Seize the changes in external conditions

The IVD industry is greatly influenced by policies, technology, and market demand. For example, the centralized procurement policy led to a significant decrease in the price of chemiluminescence reagents, and companies that optimized their cost structure in advance (such as Mindray Medical) quickly seized market share. Therefore, the ability to keenly capture industry trends determines whether new products can seize the opportunity.

2. Geographical advantage: leveraging unique resource advantages

Although the early performance of domestic IVD reagents was not as good as imported products, they gradually achieved the goal of "surrounding cities from rural areas" through low cost, localized services, and grassroots market penetration. Nowadays, domestic reagents can compete with imported brands, thanks to their deep control over industrial chain resources.

3. Special understanding: Breaking through bottlenecks with cross-border thinking

IVD is an interdisciplinary industry that involves multiple fields such as biology, mechanics, and optics. For example, when peers focus on detection accuracy, some optimize transportation and storage processes through freeze-drying technology, reducing costs and improving stability. This differentiated cognition often opens up new tracks.

How to select the correct innovation direction?

Evaluate competitors: IVD products have a long launch cycle (3-5 years), and it is necessary to predict how many teams have the same "timing and location". If there are too many potential competitors, the plan needs to be re optimized.

Systematic analysis failure cases: For example, quality control deviation may arise from assignment errors, calibration biases, or unit conversion issues. Only by digging deep into the roots can we avoid repeating the same mistakes.

Why is screening more important than blind innovation?

Some people believe that 'excessive screening will suppress innovation', but in fact, the core of corporate innovation is success rate. A management expert pointed out that "excluding 90% of ideas is economically cost-effective." This is especially true in the IVD industry - many founders come from research backgrounds and are accustomed to pursuing "breakthrough innovation," but the industry needs more practical solutions.

Balancing innovation and risk, creating differentiated products

Schwarzman of Blackstone Group once said, 'Don't consider why others don't do it,' but this applies to a minority with extremely strong resource endowments. For most enterprises, rational evaluation and differentiated competition are the key to success.

In the field of IVD, the selection of raw materials directly affects product performance. For example, Desheng New Materials focuses on the research and development of IVD core raw materials, providing high stability, low inter batch difference antigen antibodies, enzyme preparations, and other diagnostic reagent raw materials to help customers break through technical bottlenecks and shorten research and development cycles. Empowering innovation with high-quality raw materials is not only the key to success for IVD enterprises, but also the key to success.

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us