Risk control and cost optimization in the development of raw materials for in vitro diagnostic reagents

Release time:

2025-05-05

In the thriving modern industry of in vitro diagnostics (IVD), the importance of raw materials for IVD reagents is self-evident. These raw materials are the foundation for building reliable diagnostic reagents, from common blood glucose detection reagents to complex genetic diagnostic reagents, the performance of each reagent is closely dependent on the quality of the raw materials used. Reliable raw materials can ensure that diagnostic reagents have high sensitivity, high specificity, and good stability. Therefore, in the development process of in vitro diagnostic reagent raw materials, implementing risk control and cost optimization strategies is crucial for ensuring product quality and maintaining enterprise competitiveness.

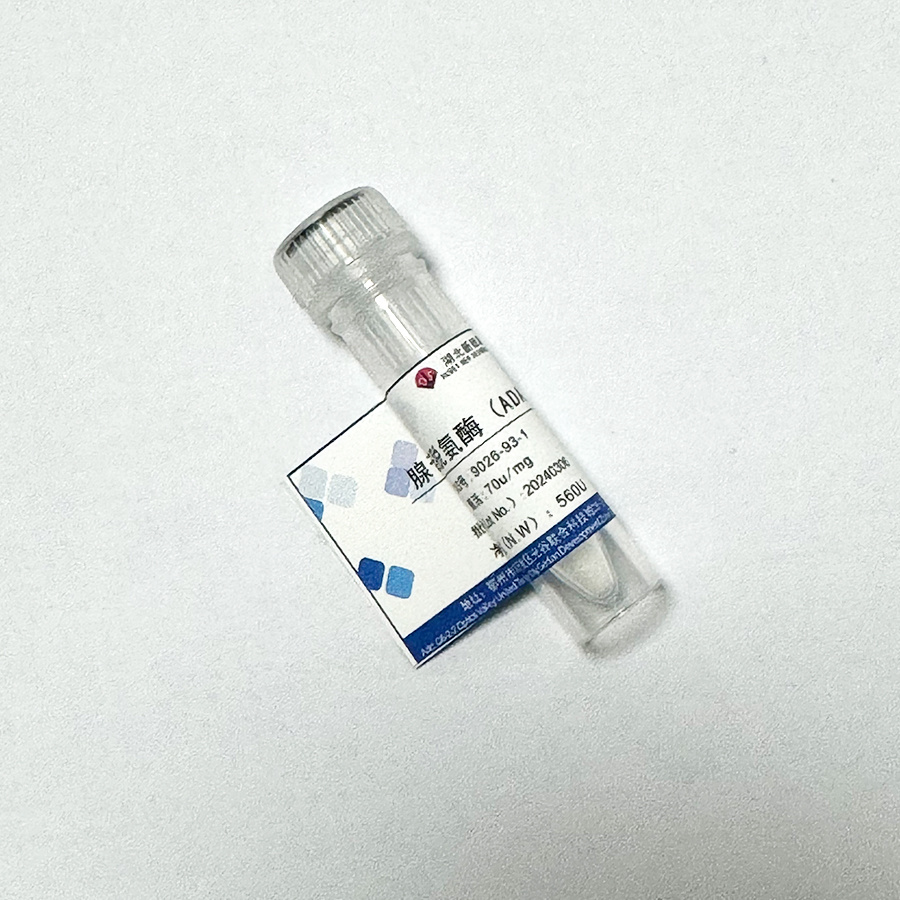

(Adenosine deaminase, raw material for enzyme preparation)

1、 Batch record integrity: guarantee of full traceability throughout the entire chain

Batch record integrity is a key link in risk control for the development of in vitro diagnostic reagent raw materials. Starting from the source of raw material procurement, detailed records of key data such as supplier information, procurement time, batch number, etc. for each batch of raw materials. In the production process, record the process parameters, equipment operation status, operators and other information to ensure that every step of the production process is traceable. In the quality inspection stage, detailed records of various testing indicators, testing methods, testing results, and quality inspection personnel of the raw materials are kept. Only raw materials that have passed strict quality inspection can proceed to the next stage. At the same time, sample retention work cannot be ignored. Each batch of raw materials must be retained according to regulations, so that traceability and re inspection can be carried out in case of problems in the future. This full traceability system from raw material procurement to production, quality inspection, and sample retention can quickly locate the source of quality problems in raw materials and take corrective measures when they are discovered.

2、 Supply Chain Backup: Strategies for Dealing with Out of Stock Risks

Supply chain backup is an important means to reduce the risk of raw material supply for in vitro diagnostic reagents. For key raw materials, choose at least 2 suppliers to avoid the risk of stockouts caused by problems with a single supplier. If only one supplier is relied upon, once the supplier experiences production failures, raw material shortages, or other force majeure factors, there may be a shortage of goods, leading to a halt in the production of diagnostic reagents.

3、 Process standardization: the key to reducing inter batch differences

Standardization of processes plays an important role in the development of raw materials for in vitro diagnostic reagents. Standardized production processes can ensure consistent quality of each batch of raw materials and reduce inter batch differences. In the production process, detailed specifications and controls are carried out for each process step, and key parameters such as reaction temperature, reaction time, and material ratio must be strictly executed according to the standards. Through process standardization, not only can product quality be improved, but production costs can also be reduced. Because it reduces inter batch differences, avoids product rework or scrap caused by unstable quality, improves production efficiency, and reduces the operating costs of the enterprise.

4、 Key points of deep supply chain management

In addition to selecting multiple suppliers, developing a raw material substitution plan is also an important aspect of deep supply chain management. For key raw materials, it is not only necessary to certify two suppliers, but also to conduct regular mandatory switching tests. Every quarter, substitute raw materials are used to verify batch consistency. Through this method, companies can timely understand the performance of substitute raw materials, ensuring that substitute raw materials can be smoothly put into use when switching suppliers without affecting product quality. During the testing process, various quality tests are conducted on products produced using alternative raw materials, including sensitivity, specificity, stability, and other indicators. Comparative analysis is conducted with products produced using raw materials from the original supplier to evaluate the feasibility of alternative raw materials.

(Color reagent raw material TOOS)

In the process of risk control and cost optimization in the development of in vitro diagnostic reagent raw materials, Hubei Xindesheng, as a raw material manufacturer, has demonstrated reliable strength. Xindesheng always adheres to the strict quality control concept, and has established a comprehensive batch record system from the beginning of raw material procurement to ensure that every batch of raw materials can be traced. By continuously optimizing the production process and strictly controlling batch differences, we ensure stable product quality. If you have any purchasing needs, please feel free to contact us at any time!

Contact details

Contact number

Address: C8, Guanggu United Science and Technology City, Ezhou City, Hubei Province

Fax:0711-3704 589

Follow us